Skylar Rainier

Mechanical engineering student

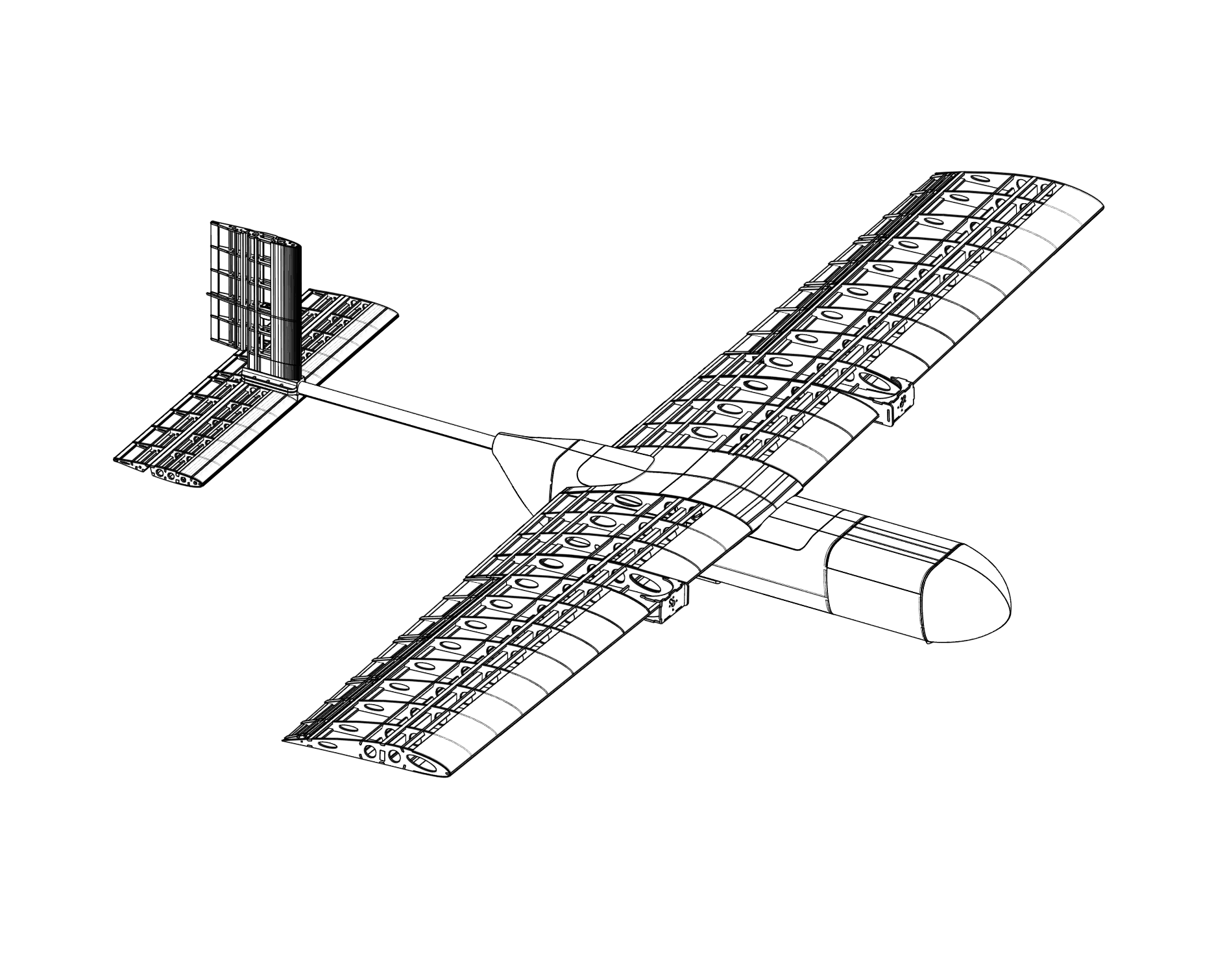

Flying Wing VTOL

The goal of this project was to rapidly build a test aircraft for AERO’s electrical subteam to test control software. The result is a tail sitter VTOL with a 1 meter wing span that has been designed to be quickly iterated upon.

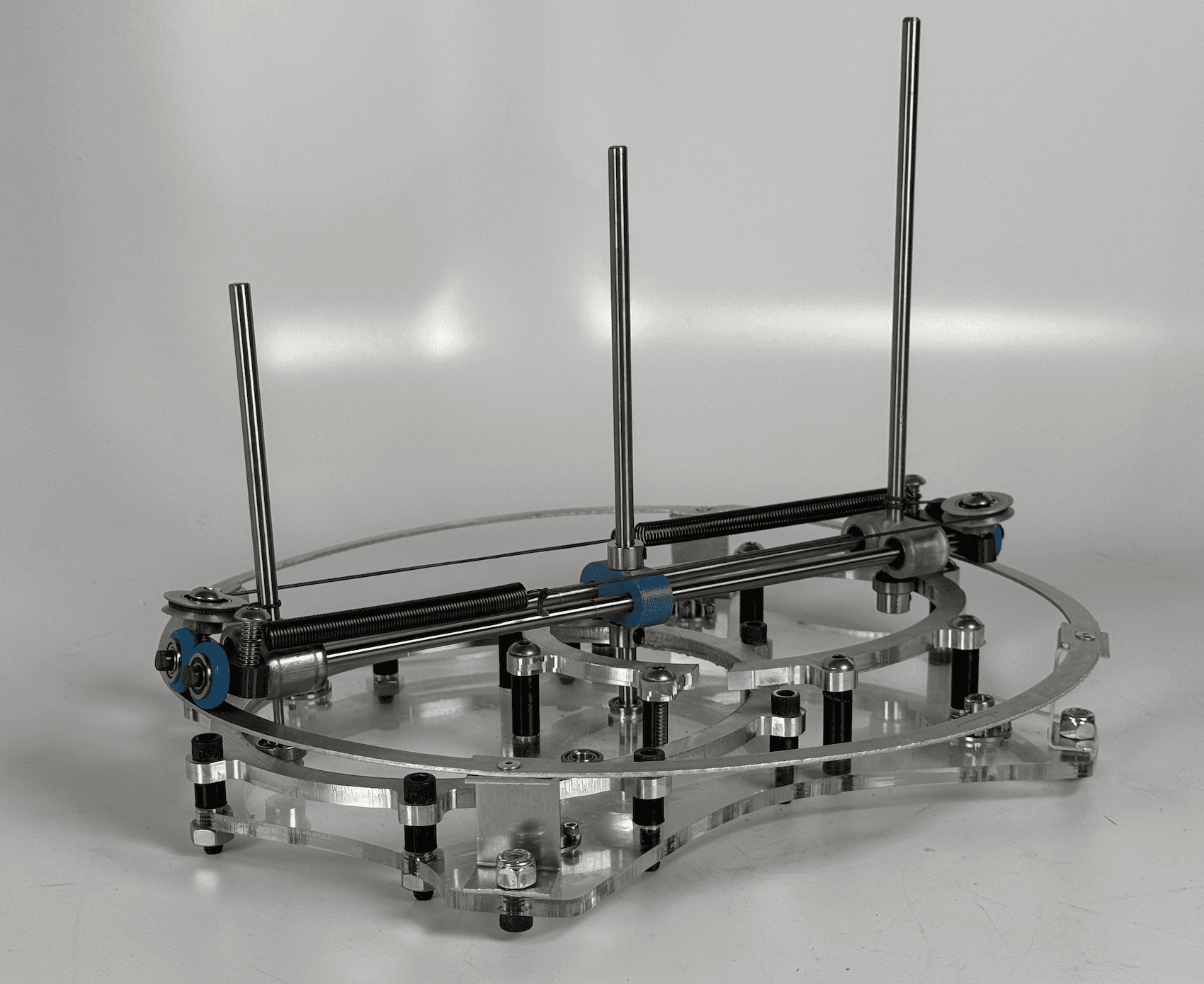

Team WebsiteMechanical Astronomy Model

A first of its kind mechanical astronomy model designed to simulate the motion of binary star orbits. This project resulted from my fascination with vintage astronomy models and desire to practice CNC machining.

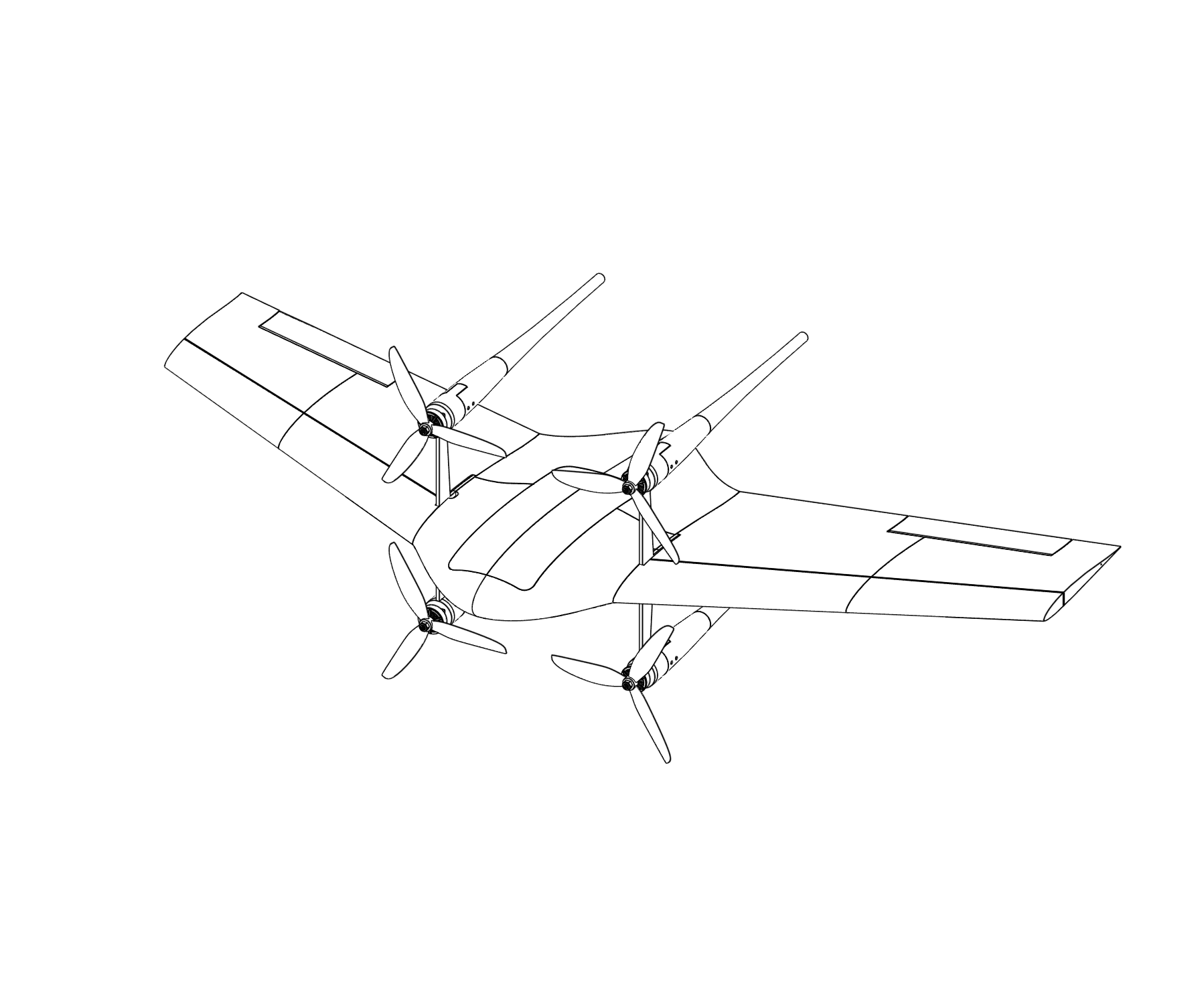

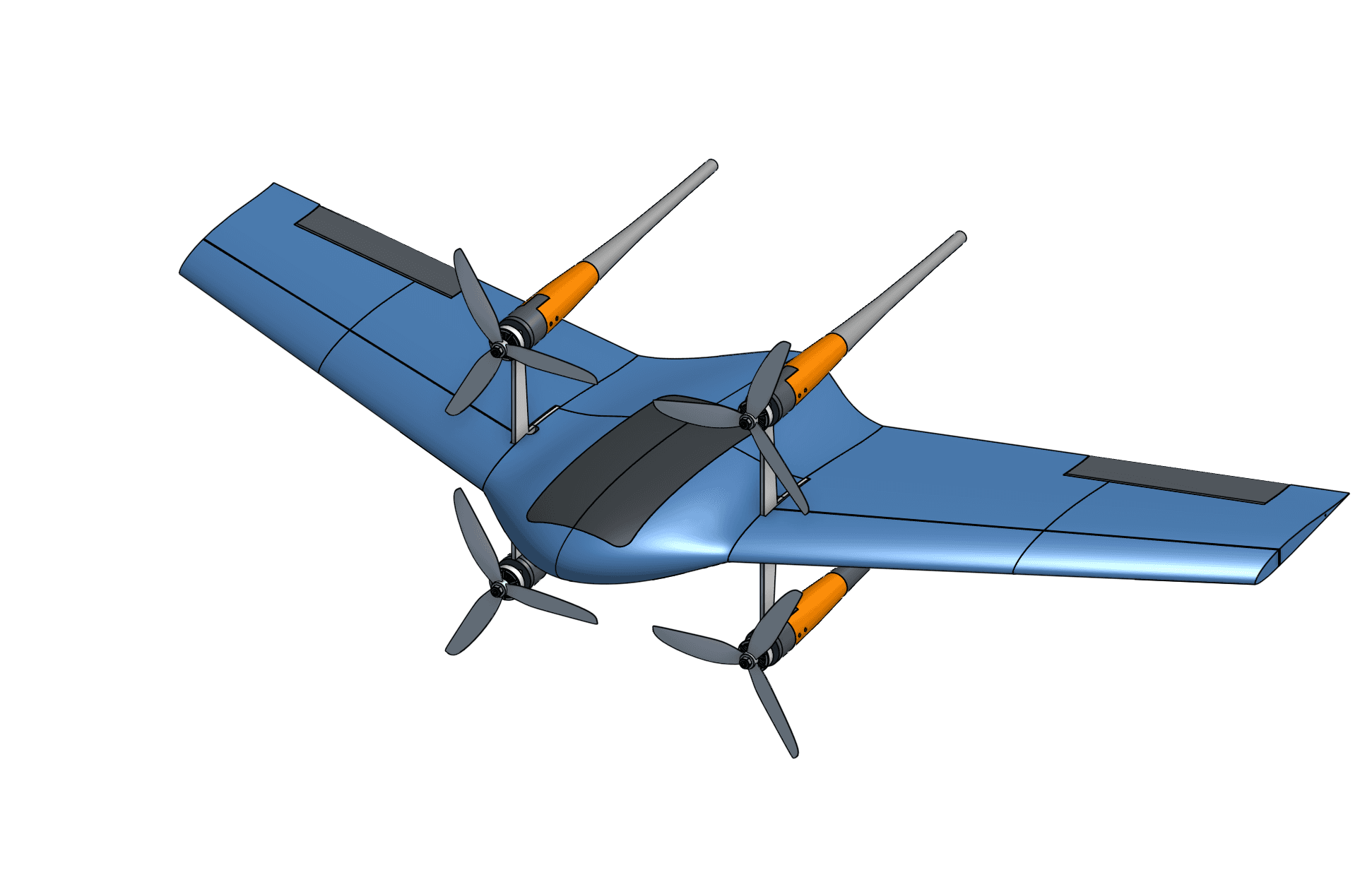

SAUS Wing & Fuselage

For AERO’s 24-25 aircraft I designed the aircraft's fuselage section and the internal structure of the wing assembly. I was also responsible for managing component integration between the mechanical and electrical subteams.

Team WebsiteShop Fellowship

Over the summer following my first year I worked for Olin Machine Shop helping to design and fabricate new shop infrastructure.

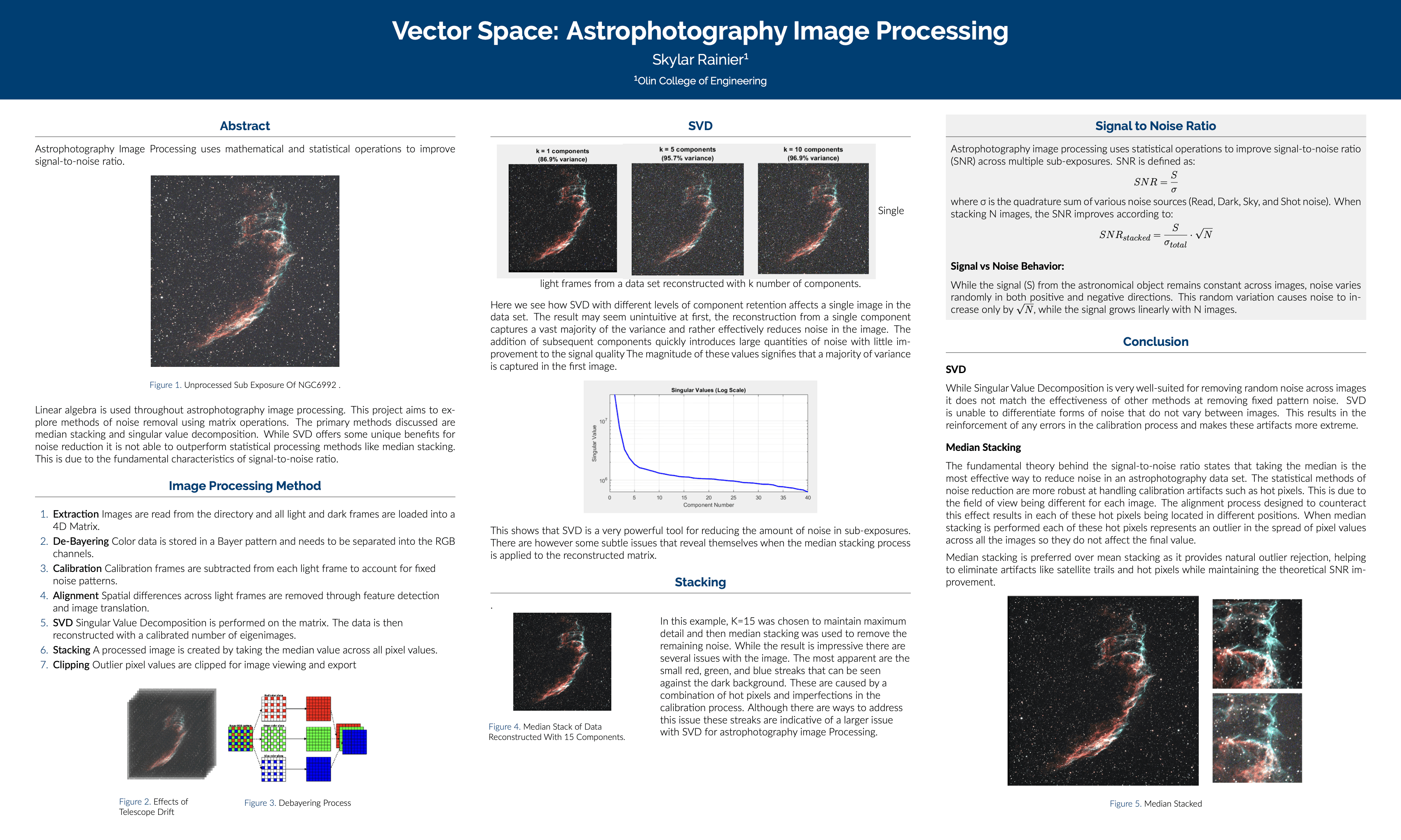

Image Processing

My final project for my Linear Algebra course in which I applied singular value decomposition to write my own Astronomy data processing tool and used it to create an image out of data I collected using a camera and telescope.

Resume

Education

Olin College of Engineering · B.S. in Mechanical Engineering

May 2028

GPA 3.92

- Course Topics: Modeling & Simulation, Differential Equations, Mechanical Prototyping, Circuit Design.

- Course Projects: CNC-Machined Astronomy Model, Facial Recognition Algorithm, Pitot Tube Airspeed Sensor.

Experience

Olin Machine Shop · Summer Fellowship

June 2025 – August 2025

- Machined parts on a CNC mill, referenced engineering drawings, and held necessary tolerances.

- Practiced MIG welding by designing and fabricating a metal structure to support a 200 lb dust collection system.

- Designed and fabricated aluminum spacers and plates used to precisely join the surfaces of two table saws.

SAUS Project Team · Co-Project Manager

September 2024 – Present

- Co-led AERO's competitive collegiate SAUS project team building a 22 kg vertical takeoff and landing (VTOL) UAV for the national competition circuit.

- Doubled the team budget and tripled membership within three months through sponsorship outreach and team marketing.

- Developed an end-to-end plan for the design, fabrication, and test flight of the first prototype within a single semester.

- Manage project team progress through design reviews, a Gantt chart, and Onshape product management tools.

- Designed and fabricated a carbon fiber composite fuselage for the previous year's aircraft.

Olin Brush Fire Attack Drone · Mechanical Subteam

September 2025 – Present

- Collaborating with a small team to design a 70 kg commercial firefighting drone through an on-campus technical startup accelerator.

- Applied FEA to select carbon fiber tubes for drone motor arms based upon given loads and acceptable deflection angles.

- Conducted materials science testing on carbon fiber tubes to experimentally find bending modulus, compressive yield strength, and fatigue loading.

- Used CNC machining to fabricate custom aluminum test fixtures for affixing and loading carbon fiber tubes.

Leadership

Olin College President's Office · Presidential Action Collaborative

December 2024 – Present

- Long-term member of an elected committee that advises the President of Olin College on student issues; advocated for students participating in project teams, utilizing shop spaces, and pursuing entrepreneurship.

- Presented to the board of Olin College, conducted user experience research on Olin's curriculum, and pitched a cross-campus entrepreneurship initiative for the President of Babson College.